How does it work?

OK, so what is so special about a Syncro? Well they are probably one of the strongest and most versatile vehicles every produced & certainly (in my book) the BEST VW Transporter ever made.

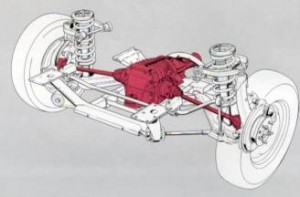

For those of you unfamiliar with the vehicle, it is fairly easy to spot once you start looking (hard). It sits about 25cm higher than a normal van (55cm if you are lucky enough to have a 16” Syncro). This is because the vehicle has its own sub frame to carry its 4-wheel drive system. Over the years this has confused many people who have not seen Syncros before & believed them to be customised vehicles. It is nice to be able to look down on Range Rovers!

Having four – wheel drive means that VW had to move some other bits about. The petrol tank was relocated to the rear over the gearbox & the spare wheel also had to be located inside the vehicle. The Syncro does have a special gearbox. In addition to an outlet to a drive shaft to the front differential (viscous coupling) it has 4 gears plus a very low ratio “ (G or Gelande – cross country) crawler gear” for any times you might be “inclined” to go or down extreme slopes.

To allow for the odd occasion that you might loose drive to both rear and/or the front wheels the Syncro was fitted with diff locks. Not all vehicles were fitted with both rear & front locks, but most if not all of the ones imported into the UK were. These are needed because, unlike more rugged of road vehicles the Syncro suspension & drives were not articulated enough & ride height still too low to avoid grounding out in the most extreme conditions.

The diff locks are basically vacuum operated solenoids which operate to lock either front or rear diffs (or both) They should not remain engaged during normal road use.

|

|

|

The basic suspension system remains the same as the normal transporter although uprated springs & dampers are fitted. In the engine bay the Air cleaner was uprated to give better off road protection. Under the vehicle extra plating is fitted to protect the underside components of the vehicle. A very welcome (and often overlooked) addition fitted to the later Syncro was the rear window vents, which allowed a cool flow of air through the interior of the van without having to open the rear windows. Apart from that (& the four wheel drive system) most of the rest of the van is the same as a normal transporter.

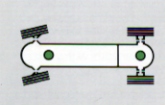

How does the Syncro bit work? Well being a Volkswagen, the boffins decided that it had to be a simple system to use & work without the driver having to operate any extra controls for normal use on the road. That ruled out most conventional systems currently in use. This is why they opted for the British Ferguson “FF” System.

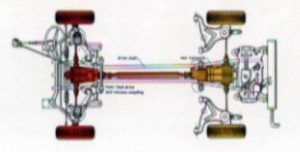

This invention uses a viscous coupling instead of a central differential. This coupling comprises of a sealed drum shaped housing containing and cooled by a silicone liquid all built into the front differential unit. Inside the drum are two independent slotted & perforated sets of discs. One set is joined via a splined shaft to the prop shaft, which in turn connects to the gearbox. The other connects to the front final drive pinion.

The Silicone fluid flows between these discs & the only transmission of power between he discs occurs via that liquid when there is a difference in speed between drive & output of the rear wheels. When the rear wheels (significantly) loose grip or spin then the coupling locks and transfers drive to the front. The viscous drive coupling does allow slight differences in speed between front & rear.

|

The Silicone fluid flows between these discs & the only transmission of power between he discs occurs via that liquid when there is a difference in speed between drive & output of the rear wheels. When the rear wheels (significantly) loose grip or spin then the coupling locks and transfers drive to the front. The viscous drive coupling does allow slight differences in speed between front & rear.

Syncro front differential |

Silicone is different to silica! |

Syncronicity

I have had a long and happy association with Syncro’s. When they were first introduced I borrowed a Syncro Panel Van a couple of times from the VAG/Mann distributors @ Swindon to do the (pre BVF) “Bug In” event at Malvern. (We just missed out being able to use their Tristar Demonstrator!)

Then in 1993 (at BVF) I managed to get my own 2.1 Caravelle Syncro. It is a 1989 model & came complete with a tuned stainless Autocavan “Powertorque” exhaust which, despite being repaired a few times is still on it.

It also came with a set of bull bars which were extremely useful & saved the front of the vehicle being caved in on more than one occasion but have now been removed as it is no longer the correct or accepted safe thing to have on the front of on road/off road vehicle in the UK.

Syncro has pole position on drive – Porsche has to rough it in garage!

It has proved to be a really fantastic vehicle & I have not seen anything that can really match it for quality or versatility since so I have kept it. It has been a brilliant workhorse & has grown up with the family. We only needed two seats when we got it now we need six! It has carried incredible loads, towed just about everything & pulled out numerous tree stumps (and stuck vehicles @ VW events!) It has been an essential part of the team at all the Vanfest events during the build ups & throughout the show weekends (and has the dents to prove it!)

It has now done 130K on original engine & clutch with no major problems.

My Syncro with its original bulbar furniture (it sits 2cm higher without it!)